Our Products

ProCone’s core technology is intended to be innovative and effective. ProCone has developed, engineered, and designed a new concept of delivering technology, which incorporates all the equipment for the conversion of carbon based materials to valuable energy, chemicals and fuels to support ProCone's rigorous, conscious and responsible materials handling and management. The core technology is the BASURAgas® universal system, consisting of the high-performance gas generator, the gas cleaning system, the combined heat and power plant, the downstream synthesis systems, the CO2 capture and sequestration and other commercially available conversion components.

ProCone’s core technology is intended to be innovative and effective. ProCone has developed, engineered, and designed a new concept of delivering technology, which incorporates all the equipment for the conversion of carbon based materials to valuable energy, chemicals and fuels to support ProCone's rigorous, conscious and responsible materials handling and management. The core technology is the BASURAgas® universal system, consisting of the high-performance gas generator, the gas cleaning system, the combined heat and power plant, the downstream synthesis systems, the CO2 capture and sequestration and other commercially available conversion components.All conversion equipment is proven technology that ProCone has aligned and will offer to their clients' as a total integrated system. ProCone is well situated to serve the industry as it has contracted multiple technology providers fitting every clients’ needs and requirements to build the perfect 'Bio Refinery'.

ProCone has aligned with third party technology providers to offer even a wider range of conversion technologies producing Bio-Diesel and Bio-Jet-Fuel, Maritime Fuel, many other liquid products, paraffin wax, carbon black, hydrogen and others combined with carbon capture and sequestration. ProCone offers these systems globally, for a market segment with a feedstock throughput of a minimum of 15,000 metric tons, to a maximum of 60,000 metric tons per year per system line.

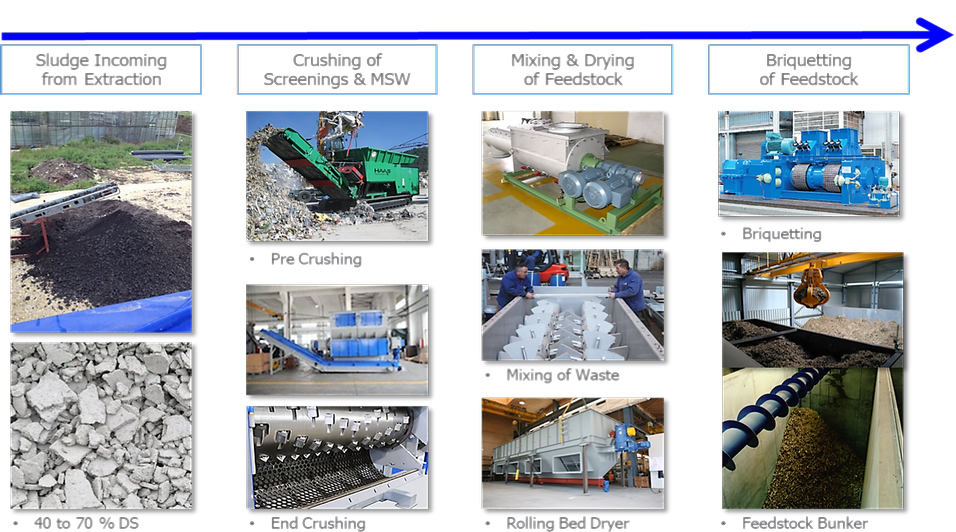

Feedstock Material Treatment

ProCone has established a very close relationship with different suppliers of mechanical and thermal materials treatment equipment. Depending on the materials available for the conversion in the BASURAgas® Universal System, different methods are employed. See below a small portfolio of equipment accessible to ProCone to treat the incoming feedstock material.

Gasifier

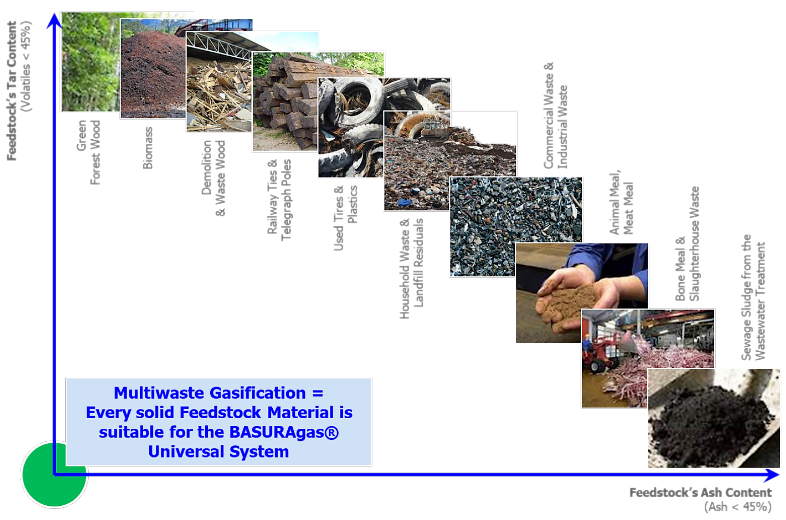

ProCone supplies gasifiers for thermo-chemical conversion of solid feedstocks into usable synthetic gas (SynGas). Our high efficiency gasifier is the core piece of our technology. ProCone is focused on providing innovative conversion technologies for processes using the most efficient methods and technologies. ProCone supplies gasification systems for different applications in various sizes from 6 MW up to 30 MW chemical gas output per unit.

The Gasification Process

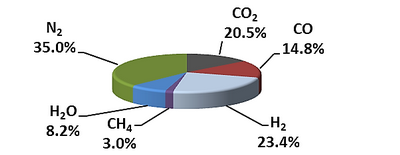

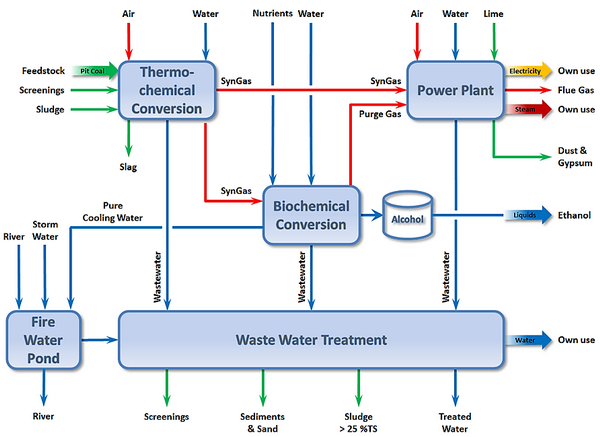

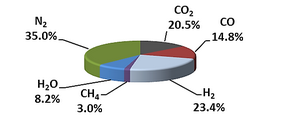

The aim of the thermo-chemical conversion process (gasification) is to generate in a gasifier, a synthesis gas or a raw gas (SynGas) from the thermal conversation of biogenic solid materials (feedstock materials) such as wood, waste of any kind or coal. The calorific value of such SynGas is generally less than 8 MJ/m3. By-products of the process are ash (vitrified slag) and exhaust heat (heat loss and drying of combustibles).

In addition to the feedstock, a gasification agent is required, which normally consists of air. Higher heating values of the gasifier can be achieved with the addition of enriched oxygen or with the addition of steam condensation. A typical process arrangement converting feedstock using air as the gasification agent, into SynGas, can be seen in the chart.

The SynGas production, as well as the drying, pyrolysis and combustion, is a part of the process that takes place in any normal combustion. An ignition of the resulting gas is prevented by lack of oxygen, and by extrication of the gas from the gasifier.

The important feature of the gasifier and essential difference from normal combustion, is the temporal and spatial separation achieved in the production of the gas, respectively the non-ignition of the gas and thereby the utilization of it.

Gas Cleaning

EXClean-2000© is our proven gas cleaning technology which is able to convert the gases produced by the BASURAgas® Universal System to high quality SynGas. The raw gas flows through several processes of purification steps to achieve the defined final quality to specifications. The following purification steps are employed in each case depending on the fuel quality and the gas quality required by the further application.

The following main steps are taken in the gas cleaning equipment:

- The produced SynGas is cooled from 600°C and up to 800°C, down to 120°C. During this process, cooling agents such as air, water, steam or oil heat-transfer units are used. The coolant agent is determined by the individual utilization of the generated excess heat. If the feedstock material moisture is too high for direct processing in the gasifier the excess heat is used for drying purposes. The rest of the excess heat can be made available for heating and cooling purposes in the surrounding area of the plant.

- The SynGas is afterwards slaked to 70°C with water. The coarse dust is removed from the SynGas while the gas is saturated with steam.

- Now the SynGas is washed with the “Venturi scrubber”. In this process the fine dust is reduced to less than 1 mg / Nm3. Dust, corrosive gas and heavy metals are being separated from the SynGas and shifted to the wash water.

- If the SynGas contains Sulphur, a separate biological gas wash is necessary which is placed downstream of the SynGas purification. It separates the hydrogen sulfide, which otherwise is not soluble, in wash water.

- This step contains the SynGas transfer and compression process to the required final pressure to specification, depending on the further application (which varies).

- Further SynGas cooling, condensation of the moisture content and mechanical drying is now achieved of the now pure SynGas to reach final specification. The SynGas condensates are separated and supplied to the wash water of steps 3 and 4.

- The last step is the separation of mercury from the SynGas by amalgamation in non-ferrous metal or in stainless steel catalysts. This is connected to an external downstream equipment for mercury recycling. The choice of the process strongly depends on the mercury content of the feedstock materials.

- The SynGas can be extra purified after step 1 to 7 by using different molecular strainers according to the intended usage of the SynGas. Accordingly a partial or close to an entire separation of carbon dioxide, water or hydrogen sulfides can be achieved to allow special usage of the SynGas.

The main advantages of the wet SynGas purification by our gas cleaning equipment lies in the shift of the acid production (fluorine, chlorine and Sulphur) as well as the alkalizing elements (heavy metals like lead, zinc, cadmium, etc.) in the wash water of the SynGas scrubber. In the process of the BASURAgas® Universal System these materials are produced mainly in basic and not in an oxidized form. In addition, the gasification process reduces the nitrogen that is contained in the feedstock materials to ammonia. During the gas scrubbing process the ammonia is bound as an ammonium in the water and leads to a very basic wash water (pH factor from 9 to 12). Thus, the heavy metals do not dissolve in the wash water and can be filtered through simple sludge removal (centrifuge, filter press) from the wash water. At the same time the ammonium serves as a neutralizing agent for chlorine and sulphur which supports the recycling of those valuable materials.

Therefore, the products resulting from the gas cleaning system can be recycled by the wastewater treatment plant and used as valuable materials:

- Chlorine: Chlorine reacts with ammonium and becomes ammonium chloride which can be sold as a cleaning agent.

- Sulphur: Sulphur reacts with ammonium to convert to ammonium sulfate and can be sold as a nitrogen (Cultan Fertilizer) fertilizer.

- Heavy metals: Since the heavy metals exist in a basic form, they can be melted down for material recycling.

The perfect combination and optimized steps of the SynGas and wash water processing, results in nearly an entire recycling of all elements contained in the feedstock material. Valuable materials will be recycled during the conversion. No valuable residue from the original feedstock material stays behind.

Bio-Chemical Conversion

ProCone provides a patented gas fermenter for the bio-chemical conversion of synthetic gas (SynGas) to liquids and gaseous raw materials for use in chemical and energy applications. The microorganisms (patented) are specified to the respective targeted product to produce ethanol, butanol, isobutene, isoprene and others. The advantages of ProCone’s SynGas conversion fermentation process is the very low process pressures (0 to 150 mbar) and the possibility to process SynGas with relatively high nitrogen content. By accelerating the reaction time in the process, the overall size compared with conventional fermenters is substantially reduced. This also leads to a significant reduction of manufacturing costs (body size) and operating costs (no oxygen plant, low power cost).

The high efficiency fermenter from ProCone is not only a more economical unit as conventional fermenters, but also requires much less of a footprint at the facility, less maintenance time and therefore less downtime of the operation.

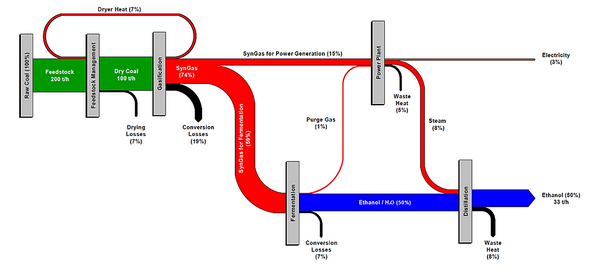

Below is a typical process flow diagram and a mass balance sheet for a coal to ethanol plant.

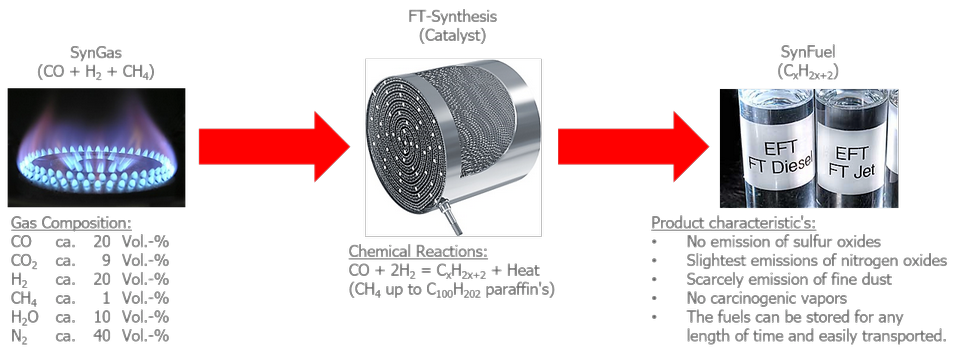

Fischer-Tropsch (FT) Synthesis

ProCone provides a chemical reactor unit based on the Fischer-Tropsch (FT) synthesis principals for the conversion of synthetic gas (SynGas) to liquids and paraffin wax. The liquids produced include diesel, jet fuel and much more. The paraffin wax produced is of high purity. The advantages of the FT synthesis unit used by ProCone is the advanced and cutting edge technology and method to deliver a very compact unit. This also leads to a significant reduction in manufacturing and operating costs. In addition the Fischer-Tropsch synthesis allows a dynamic and load flexible operation.

ProCone provides a chemical reactor unit based on the Fischer-Tropsch (FT) synthesis principals for the conversion of synthetic gas (SynGas) to liquids and paraffin wax. The liquids produced include diesel, jet fuel and much more. The paraffin wax produced is of high purity. The advantages of the FT synthesis unit used by ProCone is the advanced and cutting edge technology and method to deliver a very compact unit. This also leads to a significant reduction in manufacturing and operating costs. In addition the Fischer-Tropsch synthesis allows a dynamic and load flexible operation.The high efficiency of the conversion units is not only a more economical unit as conventional FT synthesis equipment, but also requires much less of a footprint at the facility, less start-up time, less maintenance time and therefore less downtime of the operation.

See below the advantages of thermo-chemical conversion using the FT synthesis unit to convert the SynGas into valuable liquids, for example, SynFuel and paraffin wax. Compared to conventional diesel, various kinds of regulated and non-regulated pollutant emissions are reduced with the engines using FT fuels: HC, CO, NOx, PM, SOF, VOF and PAHs. FT diesel has excellent cold starting properties, and cold start versus hot start tests show larger emission reductions for cold starts. More aggressive and more urban-like driving cycles lead to larger reductions with FT diesel, relative to conventional fossil diesel. The conversion of biomass with the FT synthesis unit used by ProCone and the use of the liquid produced, reduces the emissions of greenhouse gases by 60 – 90% compared to fossil liquids.

Hydrogen and Carbon Black Production

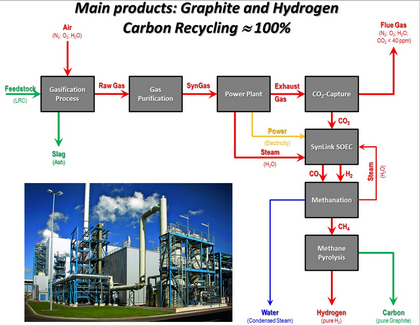

ProCone is aligned with equipment suppliers to convert the SynGas produced from ProCone’s BASURAgas® Universal System into carbon black and hydrogen. The required processes after the CO2 capturing, in combination with electricity and steam produced by ProCone’s integrated power plant, the electrolysers, the methanation and methane plasmolysis, are the newest products of ProCone.

ProCone is aligned with equipment suppliers to convert the SynGas produced from ProCone’s BASURAgas® Universal System into carbon black and hydrogen. The required processes after the CO2 capturing, in combination with electricity and steam produced by ProCone’s integrated power plant, the electrolysers, the methanation and methane plasmolysis, are the newest products of ProCone.Methane pyrolysis uses less power than other conventional systems to convert methane gas CH4. The resulting hydrogen is used without any additional process in hydrogen CHP units, boilers or SOFC fuel cells for CO2-free heat and power generation. The carbon black is used in construction, battery manufacturing, light weight construction, paints, tires and agriculture.

ProCone’s methane pyrolysis technology separates the molecular components of the CH4 into hydrogen and carbon by means of plasma equipment and not by a catalytically or at a high temperature process. ProCone’s process will convert 10 kg of CH4 and 25 kWh of electricity into 2.5 kg of hydrogen and 7.5 kg of carbon black and its therefore one of the most efficient processes available on the market.

Carbon Capture and Sequestration

Carbon capture and sequestration is the process most important for ProCone’s production of hydrogen and black carbon. If no hydrogen is produced, a part of the captured CO2 is reverted to the gasifier, the rest is saved in a water tank for future use in the process. However, the captured CO2 can be com-mercially marketed and placed to productive use in enhanced oil recovery and the manufacture of fuels, building materials, and more, or be stored in underground geologic formations. The main goal is the reduction of the CO2 output or even to be carbon neutral. ProCone offers carbon capture and sequestration equipment with a high efficiency and low operational cost and is based on the newest technology available on the market.

Carbon capture and sequestration is the process most important for ProCone’s production of hydrogen and black carbon. If no hydrogen is produced, a part of the captured CO2 is reverted to the gasifier, the rest is saved in a water tank for future use in the process. However, the captured CO2 can be com-mercially marketed and placed to productive use in enhanced oil recovery and the manufacture of fuels, building materials, and more, or be stored in underground geologic formations. The main goal is the reduction of the CO2 output or even to be carbon neutral. ProCone offers carbon capture and sequestration equipment with a high efficiency and low operational cost and is based on the newest technology available on the market.