Power plants with gas engines

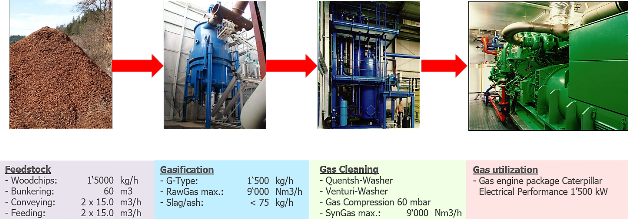

The application below shows a plant concept using wood as a feedstock material. The plant produces electricity and is a simple application to produce the electricity. The heat utilization however is very limited. This application is found mainly where biomass is available and electricity is needed locally to feed other equipment at site or to support the electrical power grid of small communities.

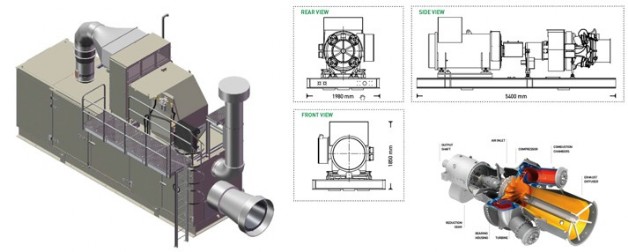

This form of conversion requires the materials treatment at the front end of the gasifier and a gas cleaner, gas compressor and power generation unit at the back end of the gasifier as the basic configuration. This application can be found in regions were electricity is in demand in combination with steam, heating or cooling requirements.

Power plants with gas turbines / IGCC – Combined cycle plant

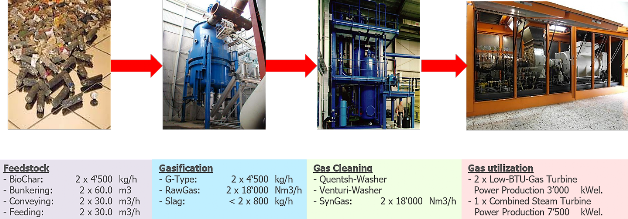

An integrated gasification combined cycle (IGCC)* system is a technology that uses a high pressure gasifier to convert carbon based feedstock materials into SynGas that is fed to a gas turbine. This power plant produces and supplies power for grid applications. Also, ProCone uses this configuration to operate their equipment and systems in bigger BASURAgas® Universal System facilities. The hot exhaust gases at the outlet of the gas turbine are directed via a heat exchanger for the production of useful heat and steam for the thermal processes of the entire plant and local steam, heat or cooling requirements.

Below is an application were ProCone is using a IGCC* plant converting BioChar as the feedstock material into electricity.

*An integrated gasification combined cycle (IGCC) is a technology that uses a high-pressure gasifier to turn coal and other carbon based fuels into pressurized gas—synthesis gas (syngas). It can then remove impurities from the syngas prior to the power generation cycle. Some of these pollutants, such as sulfur, can be turned into re-usable by-products through the Claus process. This results in lower emissions of sulfur dioxide, particulates, mercury, and in some cases carbon dioxide. With additional process equipment, a water-gas shift reaction can increase gasification efficiency and reduce carbon monoxide emissions by converting it to carbon dioxide. The resulting carbon dioxide from the shift reaction can be separated, compressed, and stored through sequestration. Excess heat from the primary combustion and syngas fired generation is then passed to a steam cycle, similar to a combined cycle gas turbine. This process results in improved thermodynamic efficiency compared to conventional pulverized coal combustion. (Wikipedia explanation of IGCC)